Linear Chain

LinearChain

The LinearChain – an innovative element in drive technology

LinearChain is an alternative to other linear drive technologies when space is limited. In drive technology, loads are usually moved by pulling or pushing; LinearChain can do both, thanks to the locking, rigid design of the links.

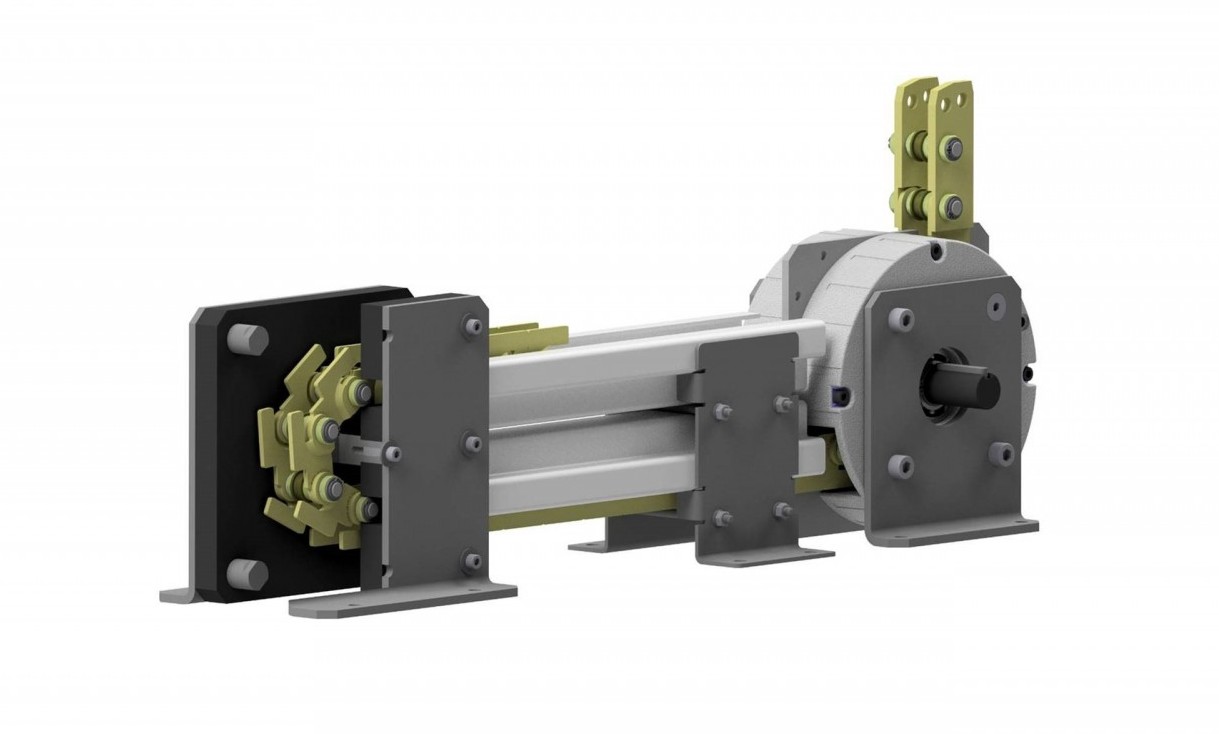

How the LinearChain works

Consisting of specially formed, high-precision mechanical chain links which interlock securely, the special feature of the LinearChain (as opposed to a “normal” chain) is that it works in both directions – it can pull and push.

In the drive housing of the LinearChain is a gear wheel which engages the chain and moves it link by link – both forwards and backwards. The chain itself has two loose ends: the load to be moved is attached to one end. The other end can be guided freely, and is usually rolled up in a storage device.

This saves an enormous amount of space, the main advantage of the LinearChain over “normal” linear drive options.

How does LinearChain push?

A pushing force is exerted on the chain links by the drive element, usually an electric motor. The unique design of the links means the shoulders of each chain link ‘lock’ into place, pushing against one another to form a rigid unit, with which they can lift or push the load.

How does LinearChain pull?

Like a normal chain, the links can be wound up in one direction and stored in a magazine, thus saving space. Paired with a drive element, the chain is pulled into that magazine, exerting a force on the load to be pulled.

How is the LinearChain guided?

You have two possibilities: either it runs over a sliding surface, or in a guide rail. The choice of guide depends on the pushing force, the stroke length and the speed of movement, and your available space. Guidance is necessary from a certain stroke length to prevent the LinearChain from buckling, for safety reasons.

Linear Chain product range

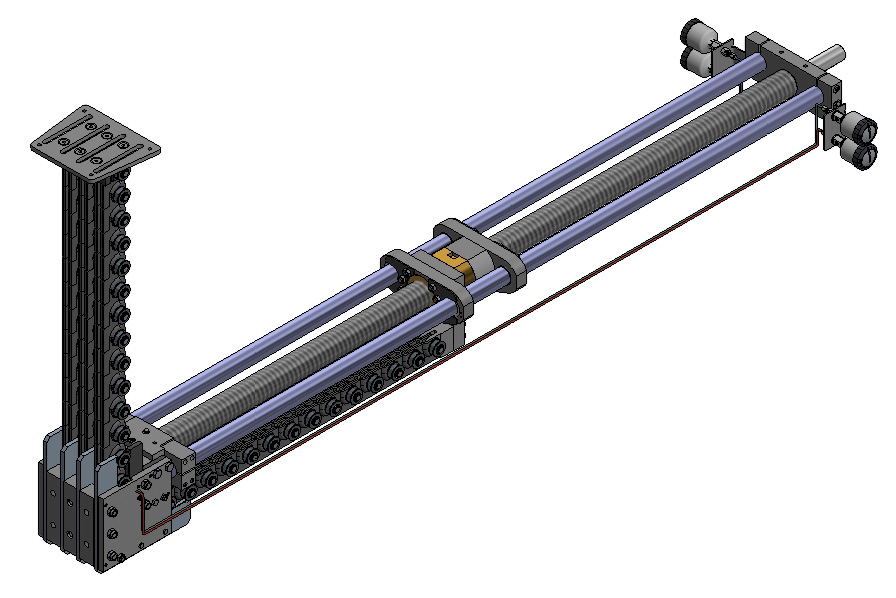

TowerChain from Grob:

The TowerChain goes the extra mile in terms of both load and unguided stroke length – achieving greater

stability over a longer distance.

SpindleChain enables constant linear force progression:

No matter what position the lifting table moves to the force to be applied to the spindle always remains the same, since the LinearChain is always attached perpendicular to the platform.

Case Studies from Grob demonstrating the Linear Chain in action

Downloads

Description

LinearChain available: thrust from 3KN to 35KN:

LinearChain SK03 (25PS)

LinearChain SK03G (25 PSG)

LinearChain SK04 (25PSR)

LinearChain SK04G (25PSRG)

LinearChain SK05 (25PD)

LinearChain SK05G (25PDG)

LinearChain SK08 (40PS)

LinearChain SK08G (40PSG)

LinearChain SK12 (40PSR)

LinearChain SK12G (40PSRG)

LinearChain SK18 (60PS)

LinearChain SK18G (60PSG)

LinearChain SK25 (60PSR)

LinearChain SK25G (60PSRG)

LinearChain SK35 (60PD)

LinearChain SK35G (60PDG)